제품/상품보기

제품상세보기

한성피엔씨 제품친환경 발포소재 및 발포시트

제품의 특징

- 가볍고 내구성이 뛰어남

- 화학소재 성분이 전혀 없는 친환경 물리발포소재

- 고객의 수요에 따라 다양한 소재의 발포시트 생산 공급

- 상세설명

- 물성표

상세설명

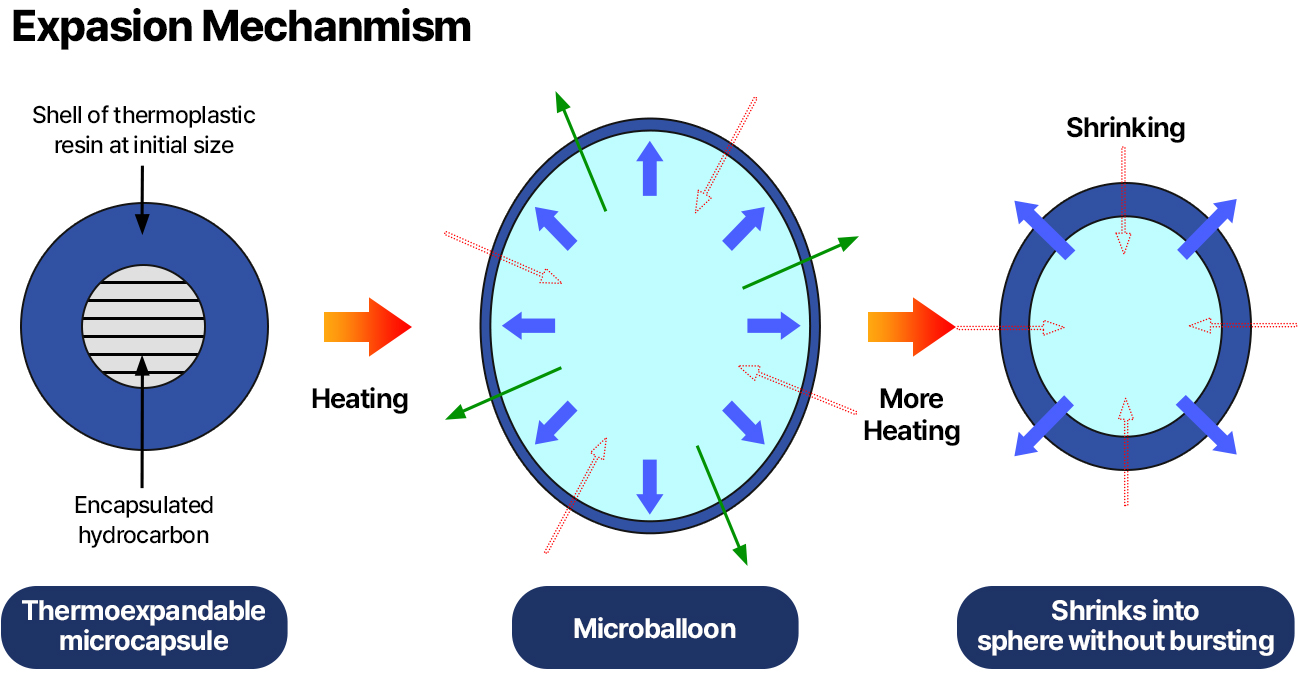

캡슐발포를 이용한 친환경 발포소재는 가볍고 내구성이 뛰어나며 화학소재 성분이 전혀없는 친환경 물리발포 소재이며 Base 수지에 Mixing해서 사용할 경우 공정이 안정되며 발포후의 밀도조절을 통해서 비중을 자유자재로 조절(0.4~0.6) 할수 있어서 편리하게 사용할수 있습니다.

자제 생산하는 발포 시트의 경우 고객의 수요에 따라서 다양한 소재의 발포시트를 생산 공급할수 있습니다.

SF TPU is a new product through foaming method that specialized in our technology. The base polymer of this foaming product is TPU. This products is eco-friendly foaming method of which expanded cell microspheres is physical foaming. Expanded cell microspheres is expanded by heat. It becomes 7 to 10 times larger than original size. It is possible to replace the present conventional foamed products.

-

- Material characteristic

- Low density

- Softness

- Eco-friendly

적용 가능 분야

Shoes outsole/Midsole, Shoes upper, Easy to high frequency cutting, Replacement of synthetic leather, Mattress

나이키 운동화

나이키 운동화 나이키 운동화

나이키 운동화 발포 시트

발포 시트

추천용도

- 자동차 내장재

- 신발용

- 일반산업용

물성표

SFTPU-120

Specification

| Property | Unit | Thickness | Test Method | |||

|---|---|---|---|---|---|---|

| 1T | 1.2T | 1.5T | 2T | |||

| Hardness | Shore A | 60 | 58 | 55 | 43 | ASTM D2240 |

| Specific Gravity | - | 0.765 | 0.739 | 0.698 | 0.481 | ASTM D792 |

| Tensile Strength | kgf/cm2 | 108 | 93 | 86 | 52 | ASTM D412 |

| Elongation | % | 466 | 421 | 445 | 483 | |

| M(100%) | kgf/cm2 | 35 | 34 | 30 | 25 | |

| Tear Strength | kgf/cm | 40 | 38 | 35 | 26 | ASTM D624 |

| DIN Abration | mm³ | 80 | 90 | 100 | 115 | ASTM D5963 |

| resistant | ||||||

SFTPU-170

Specification

| Property | Unit | Thickness | Test Method | |||

|---|---|---|---|---|---|---|

| 1T | 1.2T | 1.5T | 2T | |||

| Hardness | Shore A | 53 | 52 | 50 | 40 | ASTM D2240 |

| Specific Gravity | - | 0.724 | 0.665 | 0.543 | 0.449 | ASTM D792 |

| Tensile Strength | kgf/cm2 | 124 | 99 | 57 | 44 | ASTM D412 |

| Elongation | % | 639 | 567 | 537 | 563 | |

| M(100%) | kgf/cm2 | 23 | 25 | 23 | 14 | |

| Tear Strength | kgf/cm | 33 | 34 | 29 | 21 | ASTM D624 |

| DIN Abration | mm³ | 75 | 85 | 95 | 105 | ASTM D5963 |

| resistant | ||||||

SFTPU Technical Data Sheet

SFTPU Compared Physical Test

| list | TPU FOAM Specific Gravity ( g/cc ) | Unit | ||

|---|---|---|---|---|

| 0.4 | 0.5 | 0.6 | ||

| Appearance | natural | natural | natural | |

| Hardness( Shore-A) | 35 | 46 | 53 | ASTM D 2240 |

| Tensile Strength(kgf/cm2) | 70 | 110 | 160 | ASTM D 412 |

| Elongation (%) | 550 | 550 | 550 | ASTM D 412 |

| Abrasion resistance(Din) | 95 | 88 | 72 | ASTM D 5963 |

| Stoll abrasion | 5000↑ | 5000↑ | 5000↑ | ASTM D 3514 |

| Flex resistance(Bally type) | No crack | No crack | No crack | ISO 17694 1000,000cycle |

| UV Test | 4 | 4 | 4 | ULTRA-VITALUX 300W,24 hr |

Working Condition(extruding condition)

| extruding | Typical Value |

|---|---|

| Drying Temperature | 70℃ |

| Drying Time | 2.0 hr |

| Suggested Max Moisture | 0.08% |

| Rear Temperature | 165℃ |

| Middle Temperature | 170℃ |

| Front Temperature | 175℃ |

| dies Temperature | 180℃ |

Foaming TPU Technical Data Sheet

Foaming TPU 90H Compared Physical Test

| list | TPU FOAM Specific Gravity ( g/cc ) | Unit | ||

|---|---|---|---|---|

| 0.4 | 0.5 | 0.6 | ||

| Foaming Temperature(℃) | 180↑ | 180↑ | 180↑ | |

| Hardness (Shore-A) | 65 | 70 | 75 | ASTM D 2240 |

| Tensile Strength(kgf/cm2) | 130 | 170 | 220 | ASTM D 412 |

| Tear Strength (kgf/cm) | 50 | 60 | 70 | ASTM D 624 |

| Abrasion resistance(Din) | 95 | 88 | 72 | ASTM D 5963 |

| Stoll abrasion | 5000↑ | 5000↑ | 5000↑ | ASTM D 3514 |

| Flex resistance(Bally type) | No crack | No crack | No crack | ISO 17694 1000,000cycle |

| UV Test | 4 | 4 | 4 | ULTRA-VITALUX 300W,24 hr |

Working Condition(extruding condition)

| extruding | Typical Value |

|---|---|

| Drying Temperature | 70℃ |

| Drying Time | 2.0 hr |

| Suggested Max Moisture | 0.08% |

| Rear Temperature | 165℃ |

| Middle Temperature | 170℃ |

| Front Temperature | 175℃ |

| dies Temperature | 180℃ |

Foaming TPU 90H Compared Physical Test

| list | TPU FOAM Specific Gravity ( g/cc ) | Unit | ||

|---|---|---|---|---|

| 0.4 | 0.5 | 0.6 | ||

| Foaming Temperature(℃) | 180↑ | 180↑ | 180↑ | |

| Hardness (Shore-A) | 65 | 70 | 75 | ASTM D 2240 |

| Tensile Strength(kgf/cm2) | 130 | 170 | 220 | ASTM D 412 |

| Tear Strength (kgf/cm) | 50 | 60 | 70 | ASTM D 624 |

| Abrasion resistance(Din) | 95 | 88 | 72 | ASTM D 5963 |

| Stoll abrasion | 5000↑ | 5000↑ | 5000↑ | ASTM D 3514 |

| Flex resistance(Bally type) | No crack | No crack | No crack | ISO 17694 1000,000cycle |

| UV Test | 4 | 4 | 4 | ULTRA-VITALUX 300W,24 hr |

Foaming TPU 65L Compared Physical Test

| list | TPU FOAM Specific Gravity ( g/cc ) | Unit | ||

|---|---|---|---|---|

| 0.4 | 0.5 | 0.6 | ||

| Foaming Temperature(℃) | 240↑ | 240↑ | 240↑ | |

| Hardness (Shore-A) | 35 | 46 | 53 | ASTM D 2240 |

| Tensile Strength(kgf/cm2) | 70 | 110 | 160 | ASTM D 412 |

| Tear Strength (kgf/cm) | 30 | 40 | 50 | ASTM D 624 |

| Elongation(%) | 550 | 550 | 550 | ASTM D 412 |

| Abration resistence(Din) | 5000↑ | 5000↑ | 5000↑ | ASTM D 3514 |

| Flex resistance(Bally type) | No crack | No crack | No crack | ISO 17694 1000,000cycle |

| UV Test | 4 | 4 | 4 | ULTRA-VITALUX 300W,24 hr |